Our second attempt at a West Coast IPA, and finally a brew day that has gone largely to plan, with next to no problems or set backs! In some ways we've gone back to basics and what we know works well. More specifically, we've done away with our pump-operated sparging setup and gone back to good old manual batch sparging, as well as our trusty immersion chiller after repeated ongoing issues with our counter flow chiller not "flowing".

Starting out with our water and we've been using filtered tap water from the built-in filter from our fridge. We've done this for the past few batches and it does a good job of removing chlorine and chloramines, but still leaves the other minerals intact which we use as the base to build our water profile from.

It can take a while to get our mash and sparge water, and we end up using a 19L stock pot to transfer from the kitchen to the garage where we brewWe've got a fairly sizeable grain bill so we're starting out with 25L of water for the mash. Brewfather recommended 25.6 but we rounded it down to hopefully not have the BrewZilla quite as full during the mash.We measured out our salts/minerals and added them as per the recipe. Being a heavily hopped IPA style, we've gone for an elevated level of sulfate, so plenty of magnesium sulfate and calcium sulfate

Adjusting the pH of our sparge water, which only requires around 0.5mL of phosphoric acid to get to the desired range. We add about half or so of this from a syringe and do the rest with a dropper to avoid overshooting the pH and getting it way too low, which has happened the past few times. We'd probably prefer this a bit lower, but 5.4 is still comfortably in the middle of the 'acceptable' 5.2-5.6 range.Here's the sack of milled grain - all 6.7kg worth. There was a tiny hole in the bag the led to some being spilt whilst pouring into the BrewZilla, but certainly most of it made it in there.Mashing in sure took some time because of the large grain bill - we got there in the endFully mashed in and after quite a bit of stirring to ensure everything is wetted and hopefully avoid dough balls, we left the grain bed to settleAfter leaving the grain bed for 10 minutes or so, we took our mash pH reading. 5.48 is again probably a bit higher than we would have liked, but once again, well within the acceptable range.Mashing at 65°C we set the pump to recirculate through our sergeant sparge head and left it to do its thing. Recirculation was pretty slow and we did quite a bit of stirring to help coax everything through

After an uneventful mash of 1 hour, we raised the temperature to 75°C for the mash out then left it for 10 minutesAt this point we could see the wort really starting to run clearWe were super careful with lifting the grain basket, and then with stirring the grain bed to help the sparge water flow. In our last brew day the basket fell back into the BrewZilla and spilt hot wort everywhere - we were pretty lucky not to have suffered any serious burns when this happened.After the sparge was complete, we took our first gravity reading of 1.060 - only a point down on what the recipe predictedWhilst waiting for the boil to start, we began measuring out our hop additions - starting with Ekuanot - our 30 minute boil addition. This one ranked highly in terms of hop survivability so figured it would be a good candidate for an early boil addition.

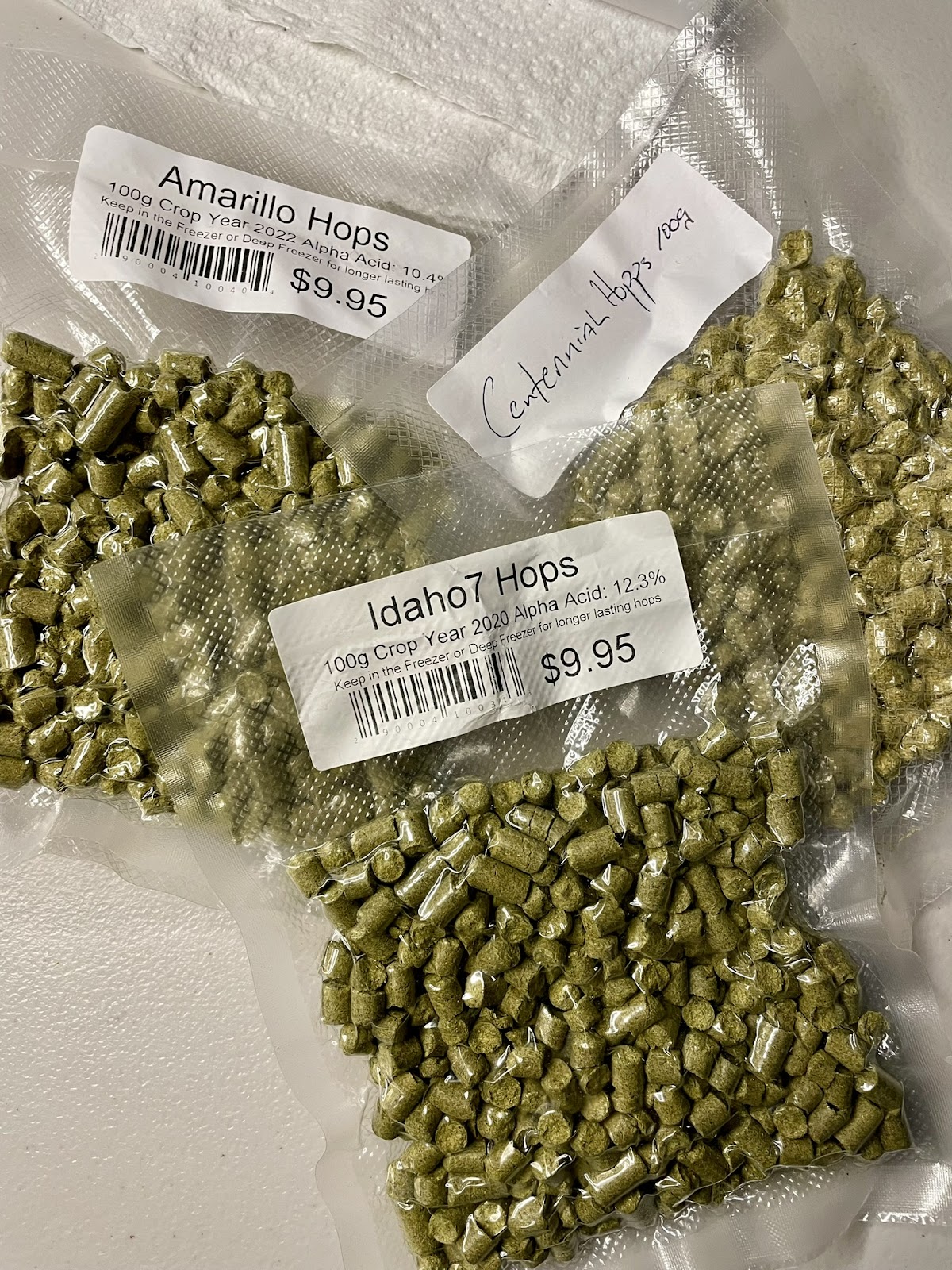

Completing the hop line up, we have Amarillo, Idaho 7 and Centennial hops. We haven't used Idaho 7 so we're keen to see what this will contribute

Nearing the boil now and we've got plenty of thick hot break forming on top - lots of stirring to prevent a messy boil over

Once the boil was underway we added our first hop addition

No more hops were needed until there was 5 minutes left in the boil, so we continued measuring our hops, as well as our yeast nutrient and half whirlfloc tablet

After our 5 minute addition, we then had a fairly substantial whirlpool hop addition as wellFor our whirlpool hop addition we chilled the wort down to 80°C then added the hops to the hop spider and recirculated using the whirlpool arm attachment for 15 minutesFor the last few minutes of the whirlpool (hop stand) we killed the pump to leave the wort to settle out a bit, and what a difference this made!We took a couple of post boil (original gravity) readings and got 1.062 and 1.064 - based on the pre boil gravity we expected 1.063 so we'll split the difference and go with thisWe've adjusted our chilling process with our immersion chiller so we now chill for 20 minutes and then transfer to the fermenter, and put the fermenter in the fridge overnight to get down to pitching temperature. We typically get to around 30°C once the fermenter is full doing it this way, so the last 10°C chilling is achieved in the fridge and we pitch yeast the next morning.

Speaking of, we pitched 2 packets of US-05 and waited for fermentation to begin

No comments:

Post a Comment