No doubt the most popular use for kegerator setups at home is to have delicious beer readily available and served from a tap - but hey, if you're reading this you probably already know that kegerator's are awesome. What you may be wondering though is the same thing we were researching a few months ago, and that is how you can run more highly carbonated beverages like soda, premixed spirits or hard seltzer in a kegerator system without pouring loads of foam every time you open the tap.

Let's start with some basics on how a kegerator system works, as you'll need to understand how this problem occurs to understand how to fix it. Your drink of choice is stored in a keg, and the headspace of this keg is pressurised with carbon dioxide gas (CO2). This gas is absorbed into the liquid in the keg until it reaches it's saturation point where it won't absorb any more gas. It is this absorbed gas that causes carbonation or the fizziness in the drink. You need to keep this same pressure applied in the headspace of the keg even after it's fully carbonated to be used as the serving pressure. The serving pressure is the pressure in the headspace that is used to "push" the liquid out of the keg through the lines and tap and into your glass.

In order for a kegerator system to work correctly, it needs to be "balanced". This balance is achieved by applying a sufficient amount of "resistance" to the liquid flowing out of the keg, through the beverage line and tap and into your glass. Failure to apply enough resistance to the liquid will result in fast, foamy pours as the carbonation (CO2 gas) rapidly comes out of solution when pouring, resulting in a flat, less fizzy final drink in your glass.

There's a number of things you can do in order to apply this resistance. Reduce the inner diameter (ID) of the beverage line being used and increasing the total length of the beverage line being used are the first two options, but you can also fit a flow control disconnect and/or flow control tap to provide even more resistance.

Let's look at a "real-world" example of how we setup our kegerator system for beer, and what we did when we wanted to serve a hard seltzer with much higher carbonation and serving pressure.

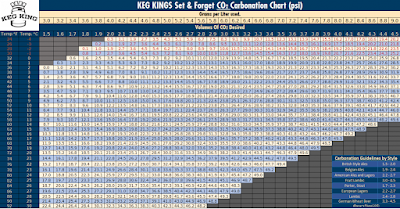

The first thing we need to figure out is what base carbonation level you're after - you can use a carbonation chart like the one below for this;

We drink mostly American Ales and Lagers, so according to the key in the bottom right corner of the chart above, we're after a carbonation range of 2.2-2.7 volumes of CO2. We prefer a bit more fizz so we'll go for the higher end of this range, and our kegerator is running at 5°C, so our target pressure is 15.5psi to achieve our desired carbonation at this temperature for our beer serving.

So we set out our beer kegs to ~15°C, and leave it to carbonate and once carbonated leave the same amount of pressure constantly connected to the keg for serving pressure.

We use 4mm ID beverage line at a length of 2.5m which gives us a good balance and provides sufficient resistance to avoid foamy pours on our beers. Everything is good, but what if one day we decide to brew a hard seltzer and carbonate it at 4 volumes of CO2 (which requires 30psi of pressure to carbonate and serve)?

Well we can tell you, running 30psi of serving pressure for a drink carbonated at 4 volumes of CO2 through 2.5m of 4mm ID beverage line will result in nothing but foam rapidly coming out of the tap. The resistance provided in this setup is just not sufficient for this pressure and carbonation level which is hardly a surprise as we've doubled the amount of pressure being used for serving when compared to what we use for our beers.

In terms of options to address this, 4mm is the smallest diameter we have available for our beverage line, so we can't change that. One thing we can do though is increase the length of line being used. We don't want to have to mess around with disconnecting our beverage line from the tap itself as it's a bit fiddly and time consuming to do so, so we can simply add an "extension" piece of line onto the existing 2.5m length to increase the total length. This is super easy by using a duotight joiner. We had a 90° elbow, but you can also get a straight joiner which is probably preferable.

Using the joiner you can add a "temporary" length of beverage line to your existing length, and once you no longer need it you can quickly disconnect and remove it and go back to your original line length. We added another couple of metres to our existing 2.5m - we haven't measured it exactly but we'd estimate a total length of at least 5m now. This helped reduce the foam during the pours, but still wasn't quite "balanced" as we needed it and there was still too much foaming for our liking.

The next thing we did was added a flow contol disconnect onto our keg which allows us to further restrict the flow rate coming out of the keg - and when combined with the increased beverage line length we were able to get the resistance required for a nice pour at 30psi without excessive foaming. Flow control disconnects feature an adjustment dial on the top so you can adjust how much resistance is applied. Our is probably 90% open, so it's only applying a small amount of resistance but it made a big difference to the quality and consistency of our pours when running much higher carbonation like we required for our seltzer.

Using just the flow control disconnect on it's own with 2.5m of beer line wasn't sufficient, and neither was using a "regular" disconnect with the increased line length. It was only when we used both the increased line length and flow control disconnect in conjunction with each other that we got the result we were after.

You can see in the picture above of our setup - the black/yellow flow control disconnect and the grey 90° elbow joiner that connects our two separate beer line lengths together.

Yes, having metres of beer line coiled up in your kegerator can get a little bit untidy, but it's worth the compromise to get the ideal pour and not lose all your carbonation when serving from your tap.

When running a kegerator system it's often worthwhile to run an alternative to beer - sparkling water, premixed spirit and soda combinations (like bourbon and cola) and hard seltzer are some good examples of drinks that require more carbonation than beer. By implementing an increased line length and a flow control disconnect we were able to apply enough resistance to get good, foam-free pours at 30psi of pressure, and if we want to go back to serving beer on this line/tap, all we need to do is disconnect the line extension from the duotight joiner. We'll probably leave the flow control disconnect in place and just open it all the way up, but you could of course just go back to a regular ball lock disconnect as well.

No comments:

Post a Comment