What is pH?

pH is a universal method of measuring the alkalinity or acidity of water. It uses a numerical scale from 0 (very acidic) to 14 (very basic/alkaline) with 7 being considered neutral.

From a beer brewing perspective, the pH of your water is crucial to obtaining the right flavour profile for your beer as it directly impacts the flavours that are extracted from your malted grains. pH also has an impact on yeast health and therefore fermentation performance, so it really is important that pH is measured during the mashing and sparging process to ensure you're getting the best results and flavour in your end product.

If the pH of your water is too high (alkaline), it can lead to excessive extraction of tannins that can promote a dry or puckering sensation - also known as "astringency". If the pH of your water is too low (acadic) it can lead to a beer that is lacking in flavour and body, and if it's particularly low (less than 2), it can prevent brewing enzymes from becoming active.

Measuring pH

Measuring pH is simple, with pH meters being readily available and relatively cheap. It is important they're properly calibrated, but once they are you can get accurate, instant measurements of your mash and sparge water pH levels and make adjustments as necessary. Good pH meters will also have Automatic Temperature Compensation (ATC), meaning you can measure your sample at warmer temperatures and the device will compensate and adjust the reading accordingly.

|

| a pH Meter can be used to quickly and easily measure your water pH level |

pH when Mashing

For brewing beer, the recommended mash pH range is from 5.2 - 5.6 - which makes it slightly acidic. Most water sources will be neutral to slightly alkaline, meaning the water will generally need to be acidified to get it into this ideal range. Naturally, water can be acidified by adding acid directly to it - we use phosphoric acid, but lactic or muriatic/hydrochloric acid can also be used. We use phosphoric since it's less hazardous than hydrochloric and tends to be more flavour neutral than lactic acid, and phosphoric is generally used in other parts of the brewery such as sanitiser so is more readily available.

Here's where it gets tricky though. When we're talking about the pH of the mash, we have a moving target. That is, the pH of the mash will change and evolve throughout the duration of the mash - and since it is believed that the majority of conversion of starch to sugars happens quickly within the mash - within the first 15-20 minutes, there's a limited window of opportunity to make adjustments.

It's also recommended that mash pH not be measured until at least 10 minutes into the mashing process, since grains can have an impact on mash pH as well it allows time for them to do their thing.

To get the best results, we essentially need to predict what the mash pH will be, based on the pH of the source water that is added, other brewing salts that are used to adjust things like calcium, chloride and sulfate levels, as well as the grains that are being used in the mash.

No doubt this sounds confusing, but thankfully you don't need a science degree to work all this out - you can use brewing software (such as Brewfather which we use) to do all the heavy lifting here for you, and it will tell you how much acid to add to your mash to reach your desired pH level after completing your recipe.

You can then add 75-80% of the acid initially to your water before adding your grains, take a pH measurement after 10 minutes of mashing, and then make further, smaller adjustments if necessary.

Here's a screenshot taken from Brewfather of the pH adjustment calculations for a recent brew we completed.

You can see at the top of the window, the water pH for our mash is at 5.36. This has been calculated based off adding 2ml of phosphoric acid with an 85% concentration (the concentration level is stated on the acid bottle/packaging) as well as the other water adjustments that have been made (not pictured).

We like to aim for around 5.4 for our pH level as this gives a little bit of room for error so if we're a little more or less than this, we'll still be in that desired 5.2 - 5.6 range.

During the mash, after waiting for 10 minutes, you can draw a small sample from the top of the mash, cool it slightly so the sample is within the recommended range of the pH meter, then insert the pH meter probe into the solution and wait for the reading to stabilise. You can see in the image above, the reading is 5.34 - right within the 5.2 - 5.6 sweet spot for beer.

It's also worth noting that after hitting the target pH in the mash, the pH is then no longer adjusted and will typically take care of itself from this point onwards.

pH when Sparging

Although perhaps not considered as critical as mash pH, the pH of your sparge water is also important. Untreated sparge water will generally have a higher pH level and can lead to tannins being extracted from the grains which can lead to astringent flavours developing within the beer.

It is generally acceptable to have a pH level of less than 6 for your sparge water, it doesn't have to fall exactly within the 5.2 - 5.6 range like with mash water.

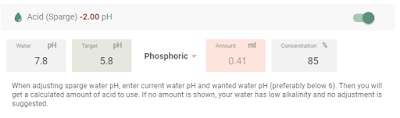

Once again, you can use brewing software like Brewfather to calculate this adjustment for you. You simply need to know the pH of the sparge water, and the desired pH level.

You can see in the image above our sparge water has a starting pH of 7.8. And to reach our desired target pH of 5.8, we only need to add 0.41ml of 85% phosphoric acid.

Conclusion

There's no doubt that the pH level of water used in brewing has a direct and significant impact on the end result. Afterall, water is the single largest ingredient in beer so it makes sense to give it the attention it deserves.

If you're not already using brewing software like Brewfather, you really should. There is a free version available that will let you use the water adjustment calculator as well as the majority of the other cool features within it.

pH meters are also a must have, especially since they can be had for around $30. We'd highly recommend one with Automatic Temperature Compensation. We use this one from KegLand.

Since the pH in the mash is a constantly changing variable, we've found using the method of adding the majority of our adjustments prior to mashing in, then making final adjustments after 10 minutes works really well and gets excellent results. Brewing software calculators are also surprisingly accurate and will generally get you pretty close to your target numbers, as long as the data you enter is accurate of course, so knowing the pH level of your source water definitely helps with this (another reason to get a pH meter!).

No comments:

Post a Comment