For beginner and experienced homebrewers alike, we believe there is always a place in their brewing equipment inventory for at least one plastic fermenter. They're simple, cheap, reliable and can produce excellent results. But not all plastic fermenters are created equally, with advancements in manufacturing technologies allowing new products to constantly push the boundaries of what is possible. The evolution of plastic fermenters has come a long way in recent years, and are completely different to the old plastic bucket style fermenters with a spigot/tap at the bottom from days of old.

Don't be fooled into thinking that plastic fermenters are inferior to those made with stainless steel either. Although stainless does have some advantages, there are certainly some advantages that PET plastic has over stainless such as it's relative light weight, transparency and cost.

Keg King have developed a range of PET plastic based fermenters, dubbed

Apollo, that boast a long list of great features to suit homebrewers of all experience levels. They're also designed and manufactured right here in Australia by Keg King.

In this review we'll be looking at the 30L Apollo Snub Nose fermenter - a closed bottom, conical style, pressure capable, PET plastic based fermenter.

|

| Keg King's Apollo Snub Nose 30L Fermenter |

Opening the box and we've got the fermenter body seated on the metal stand, and a bag with all the parts and components required for assembly. The stand is made of stainless steel and is custom designed for the Apollo with a larger top ring supporting the main body and a smaller ring situated lower down to support the snub nose. The two points of contact between the stand and the fermenter body give a rock solid foundation with no movement or risk of it tipping over.

There isn't a way for the fermenter to attach or tether to the stand though, so if you're needing to relocate the fermenter whilst full, you either need to pick it up and carry it by holding the stand itself, or have a second person move the stand to the new location on your behalf whilst you handle the fermenter, since the snub nose shape at the bottom means you can't set the fermenter down on the ground without it tipping over onto its side.

On the Apollo body there are two moulded plastic handles just underneath the lid opening that provide a really solid feel when lifting, and even with the fermenter full there was no noticeable flexing.

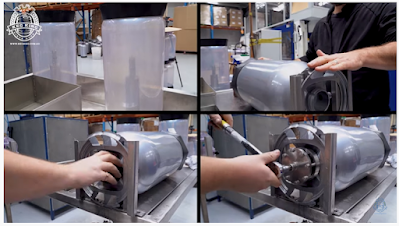

Some assembly is required but is very straightforward, with all the included parts only needing to be attached to the main lid. A poppet and spring need to be installed into the gas and liquid ball lock posts which are then screwed onto the appropriate threads on the lid. The pressure release valve (PRV) housing is then screwed onto the lid (which can be removed and then acts as a dry hopping port), with the PRV then screwing into the housing.

|

| Spring & poppet need to be installed into the ball lock posts |

The Apollo comes with two PRV's that are colour coded according to their effective pressures - purple (15psi) and blue (10psi) to ensure a safe working pressure is maintained within the Apollo at all times.

A stainless thermowell is also included that utilises a BSP thread and screws onto the under side of the lid. Once fitted it protrudes into the middle of the wort and allows a temperature probe to be inserted through the top for precise temperature measurement and control during active fermentation.

Lastly, the floating dip tube is assembled by attaching the filter and ball float together, with the filter then attaching to the silicone dip tube. The other end of the dip tube is then attached to the under side of the liquid ball lock post (the post without the small notches in it). The rings used to attach the filter and ball float together can be looped over the thermowell to ensure the floating dip tube remains centered within the fermenter as well.

|

| The Apollo's filter and ball float attached to the silicone dip tube |

A couple of tips worth noting is to use some food grade lubricant on the large lid O-ring, as well as the small seal on the PRV to help provide a leak-free seal. Also remember not to over-tighten any of the attachments. No tools should be required for assembly, and when screwing things into place, do them up firmly but not as tight as humanly possible - over-tightening can be just as problematic as under-tightening things.

All up, the lid assembly takes no more than 5 minutes to put together. Keg King have an excellent YouTube video outlining the assembly process as well which is definitely worth a look if you're putting this together for the first time.

A strip sticker with volume markings is also included along with a stick-on thermometer to help determine the temperature of what is inside the fermenter. There's a neat seam down the side of the fermenter that can be used to help align the volume markings sticker so you can get it as straight as possible when affixing.

|

| Keg King's Apollo Snub Nose 30L Fermenter |

Now that assembly is done, a quick clean is probably a good idea just in case there are any oils or other substances left over from manufacturing. We always use cold water when cleaning our plastic fermenters, though warm water can be used (up to 50°C) if you wish. We used some powdered brewery wash (PBW) and cold tap water - thrown into the fermenter then shaken vigorously to mix and coat all surfaces before giving a gentle wipe over with a soft dish cloth followed by a rinse with cold water.

A similar process is repeated for sanitising, with 1L of water added along with a small amount of phosphoric acid based no rinse sanitiser to obtain the right dilution before shaking to distribute the sanitising solution on all internal surfaces before emptying again and filling with wort.

The 115mm lid opening provides adequate space when filling, and is big enough for an adult arm to be able to reach in for cleaning all the way to the bottom. We find plastic much easier to clean than stainless since you can more easily see where any build up has occurred so you know where you need to be scrubbing - but we also love the fact that we can see the wort in the fermenter too. We still find it fascinating watching the vigorous action of fermentation once it's underway which to us is probably one of the greatest benefits of clear plastic fermenters like the Apollo.

Speaking of fermentation, did we mention that the Apollo is pressure capable? Each Apollo fermenter is individually pressure tested as part of the manufacturing process, and is rated for use up to 35psi - more than enough pressure for even the most aggressive of pressure fermentations.

Pressure fermentations are great and offer brewers the ability to carbonate their beer using the CO2 created by fermentation. It also enables fermentations to be performed faster by allowing higher fermentation temperatures and suppressing the off flavours that are often associated with those higher temperatures. Finally, there is the benefit of oxygen free pressure transfers to all but eliminate the risk of oxidation of your fresh beer as part of the transfer/packaging process - combined with the transparent plastic fermenter body allowing you to watch the progress of your transfer and stop it before any unwanted trub is picked up and transferred from the bottom. These are all benefits that brewers are able to leverage with their Apollo fermenter.

|

| Pressure transfers are a good way of eliminating oxygen ingress during packaging |

You can also fit a Spundy Spunding Valve to your Apollo to help regulate the pressure within it during pressure fermentations by attaching it directly to the gas post on the lid.

The snub nose is a key feature of the Apollo, allowing the trub and yeast cake to settle into the bottom of the fermenter. The cone-like shape means it collects nicely and takes up less surface area, allowing more of the fresh beer to be harvested from the top using the floating dip tube. There is a noticeable reduction in the left over trub in our Apollo compared to our experience using other plastic fermenters without the cone/snub nose shape.

|

| The trub and yeast collects nicely in the bottom of the snub nose |

An insulating jacket is available as an optional extra to help maintain and stabilise the temperature within the Apollo, and can also shield your precious beer once it's fermented from damaging Ultra-Violet (UV) light. There's also a stainless cooling coil available if you wish to control the temperature of your fermenting wort using a glycol chiller setup.

We previously mentioned the PRV housing can be easily unscrewed and removed to be used as a dry hopping port. A funnel may help to get hops through the relatively small opening, but we expect clogging might be a little problematic. We prefer to dry hop by simply unscrewing the collar and opening the main lid which allows large amounts of hops to quickly be added into the fermenter with minimal fuss and mess.

Since the only way to get your beer out of the fermenter is through the floating dip tube, a CO2 gas source (ie. pressurised bottle) is required to achieve this. You can capture and leverage some of the CO2 created by fermentation to do this, but it wouldn't be sufficient to move a full 20-25L of beer out of the fermenter.

What could be improved for future revisions of the Apollo? We'd like to see the lid redesigned to feature a 1.5" tri clover port to allow for other attachments to be fitted - things like dry hopping contraptions that can be purged for oxygen-free pressure dry hopping, or a carbonation stone that could be attached to a separate ball lock post then quickly/easily removed.

A way to tether the fermenter to the stand (or have handles incorporated into the stand) would also be a welcome addition to improve the ergonomics of moving it - particularly when full.

The Apollo Snub Nose comes in 30L and 60L varities, but there is another version - the Apollo Unitank which also comes in 30L and 60L sizes and features an additional collection container at the bottom. This allows for yeast and trub to be removed so you can serve directly from the fermenter for extended periods making it a true uni-tank fermenter.

We think the Apollo Snub Nose is an excellent piece of gear that will more than meet the needs of most homebrewers. The simple design makes it incredibly easy to use, and we love being able to watch how our fermentation is tracking through the transparent plastic. The snub nose feature helps to minimise wastage by reducing the amount of beer that is in contact with the trub once it settles into the cone at the bottom. All this combined with pressure fermenting capabilities means that creating high quality beer or other fermented beverages is well within reach for brewers of nearly all budgets and skill levels. Lastly, being designed and manufactured locally in Australia is a great bonus meaning using one is helping to support local business and industry.

The Apollo Snub Nose 30L model we reviewed here currently retails from Keg King for AU$85, but there is also a bundle available that includes the Spundy which is well worth considering for an extra AU$10.

Related Articles