Why Do Yeast Need Oxygen?

At every stage of the beer creation process after fermentation, oxygen is the number one enemy as it can rapidly deteriorate the appearance, aroma and most importantly the flavour of your beer in a process known as oxidation.

Prior to fermentation, however, oxygen is a critical component that is often overlooked by homebrewers. For whatever reason it just doesn't get the same attention and appreciation as other things like fermentation temperature control.

Yeast require oxygen to be present in the wort prior to and during the initial stages of fermentation for cell growth and reproduction. Yeast produce fatty acids and sterols, known as lipids which are important components of the cell membrane which influence the ability of the cells to grow and reproduce, which happens shortly after the yeast is pitched into the wort. Think of it as the preparation phase that yeast go through to prior to feasting on the sugars contained in the wort.

When wort is boiled as part of the brewing process, it drives off many undesirable compounds and makes the wort sanitary in preparation for yeast to do their thing, but it also removes most of the oxygen from the wort.

Failure to replenish the wort with sufficient oxygen prior to pitching yeast can lead to poor yeast health, which can in turn cause substandard fermentation performance and outcomes. Things like reduced attenuation (not reaching the expected final gravity), long lag times or fermentations becoming stuck or taking too long are all classic symptoms of insufficient oxygen in the wort. Poor yeast health will often mean off flavours and other undesirable compounds will end up in the finished beer. The end result - your finished beer just won't taste as good as it could.

How much Oxygen is Required?

There are many factors that determine how much oxygen is required by yeast - such as the variety of yeast strain, the amount of yeast that have been pitched (pitch rate), starting gravity of the wort and the amount of trub present in the wort.

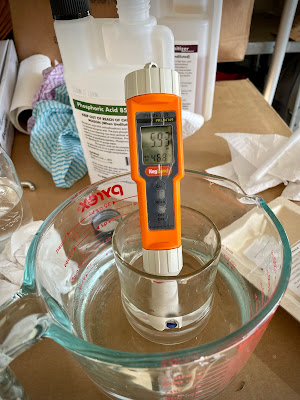

The ability for wort to absorb oxygen is dependent on factors such as gravity (the amount of sugar present) as well as temperature. The higher the gravity or the temperature of the wort, the less oxygen is able to be readily absorbed by it.

The generally accepted amount of oxygen required in wort prior to fermentation is 8-10 parts per million (ppm) with 5ppm being considered the bare minimum. It is possible to achieve 8ppm using regular atmospheric air, but levels above this will require the use of pure oxygen.

10ppm is considered the ideal amount for most fermentations, and when it comes to oxygen levels, too much is better than not enough. Yeast will typically consume all the available oxygen within 3-9 hours of being pitched into the wort, and some oxygen will also come out of solution during this time.

Oxygenation vs Aeration

When it comes to oxygenating wort, you'll often hear the terms "oxygenation" and "aeration" being used. So what's the difference?

Oxygenation is the process of adding pure oxygen to a solution.

Aeration is the process of adding regular air to a solution.

Obviously from a brewing perspective, the "solution" we're referring to is our wort, and both methods are employed after the wort has been chilled to yeast pitching temperature after boiling.

Aeration Methods

Arguably easier and more accessible for homebrewers is the aeration method. There are several ways that wort can be aerated such as;

- Vigorously stirring the wort with a mash paddle, whisk or other utensil

- Using a paint stirring attachment on an electric drill

- Covering and shaking the fermenter or carboy

- Pouring the wort between two fermenters or carboys (can be repeated several times)

- Creating a splashing effect when transferring to fermenter by using a mesh strainer or something similar

- Using a pond or other pump connected to a diffusion stone submersed in the wort

|

| An example of a pump for wort aeration |

From the list above you can see that aeration methods are typically quite manual and labour intensive. Since you're adding air, which is comprised of roughly 21% oxygen, it can take as long as 15-20 minutes to get the required amount of oxygen into the wort, and even then you won't get any more than 8ppm using aeration.

It's also difficult to know exactly how much air or oxygen is being added to your wort using these methods.

Finally, the risk of contaminants being introduced into your wort is arguably higher when using aeration methods since you're adding air from the atmosphere that may contain other microbes and particulates that may or may not lead to an infection occurring.

Oxygenation Methods

More effective and efficient that aeration, oxygenation involves adding pure oxygen directly into the wort. A source of pure oxygen (usually a tank) is required, as well as some other specialised equipment. Some common oxygenation methods are;

- A diffusion stone submersed in the wort

- Inline oxygenation that infuses oxygen into the wort as it passes from the kettle to the fermenter

Equipment such as a pressure regulator, tubing and a diffusion stone will be required to perform either method outlined above, but since you're working with pure oxygen, the process is much faster, efficient and arguably less risky than aeration, since it's incredibly unlikely any microbes or other organisms could survive in an environment of pure oxygen.

Since you're adding pure oxygen in a form of controlled dose, it's also easier to determine (albeit roughly) how much oxygen you are adding into your wort.

Using pure oxygen you are also able to reach the desired level of 10-12ppm of dissolved oxygen in your wort and aren't limited to 8ppm like you are by using aeration methods previously described.

Conclusion

There are many factors to consider when brewing a beer - water chemistry, pH level, fermentation temperature are just a few critical elements that require the attention of brewers in order to achieve the best outcomes. It makes sense then that the health of yeast is also critical, after all - brewers create wort, and yeast create beer.

On it's own, it's unlikely that oxygenating will solely provide significant gains - especially if some of the factors we mentioned earlier aren't also addressed. Brewing an excellent beer is the culmination of getting many small things right which is all part of the journey of becoming a better brewer.

It's definitely worth taking notice of advice that is repeated as often as the professional advice around wort oxygenation. When yeast manufacturers themselves who have all the science knowledge, research and testing to back up their claims advise that this is the way to go to get best results, it's best to pay attention.

Oxygenating wort is something we're going to start focusing more on in our own brewing journey in order to try and improve the quality of the beers we make.

We've recently reviewed Spike Brewing's Oxygenation Kit which is a great piece of gear to help easily and accurately oxygenate your wort. Click the link above to see the article.

.png)