Review Date: 26/11/2021

Brewery Name: Sydney Brewery

Beer Name: Pyrmont Rye IPA (definitely a missed opportunity - why is it not called a "Rye-PA"!?)

"Crafted with three varities of U.S hops, a bitter spiciness of pine & savoury malt, our Pyrmont Rye IPA presents itself as a beautiful dark amber, perfectly balanced with a sweet, fruitful aroma. Pyrmont Rye IPA really is a ripper!"

|

| Sydney Brewery - Pyrmont Rye IPA |

General

Alcohol By Volume (ABV): 6.5% (High Strength)

Label/Design: 3/10 - plain & simple design

Serving Style: Can - 355ml

Region of Origin: Pacific (Australia, New Zealand)

Style Family: IPA

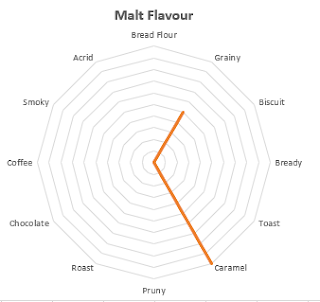

Malts/Adjuncts: Rye, Unknown

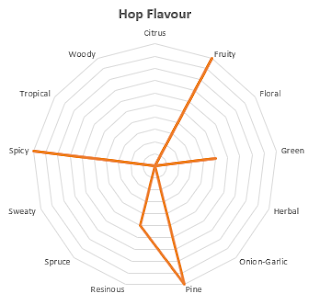

Hops: 3 US Varieties (Unspecified)

IBU's: Unknown

Appearance

Colour: Deep Amber

Collar of Foam & Head Retention: Good (more than 60 seconds)

Foam Texture: Fluffy

Alcohol Aroma: Mild

Aroma

Esters Aroma: None

Phenols: None

Flavour & Aftertaste

Alcohol Taste: Noticeable

Hop Bitterness: Aggressive

Malt Sweetness: Medium

Astringency: Low

Palate/Mouthfeel: Full Bodied (Round, Rich & Creamy)

Palate Carbonation: Medium

Length/Finish: Medium (15 to 60 seconds)

Overall

Drinkability: 7/10

Overall Impression: 7/10

Notes: Overall an enjoyable beer and a good example of an American IPA. It has strong flavours - the unmissable classic American hop flavours always pair well with the caramel notes, presumably from crystal malts being used. Enjoyable but not sessionable with plenty of flavour and alcohol content.